Our Factory

State-of-the-art machinery powering quality packaging production

Our Equipment

Advanced machinery ensuring precision and quality in every product

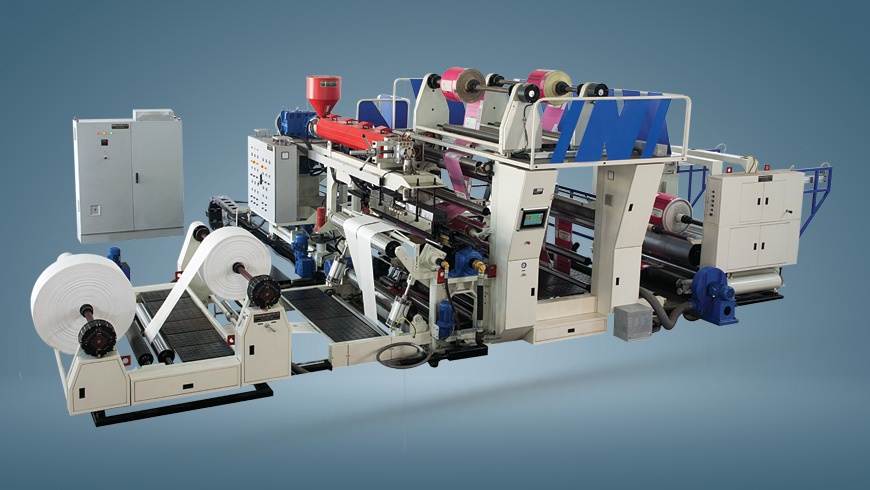

Extrusion Lamination Plant

Co-extrusion & multi-layer lamination up to 1650 mm

High-capacity extrusion lamination line with co-extrusion and barrier technologies. Ideal for flexible packaging, woven sacks, films, and laminates combining strength and barrier properties. Navrang offers models like “CHETAK 1650” and “LAMI SACK 1650.”

Twin / Multilayer Coating & Lamination Machine

Precision tension control, hot melt & adhesive coating

Advanced coating & lamination system with in-line coating heads, hot melt applicators, and tension control. Designed for uniform layers, adhesion, and high throughput in films and packaging substrates. Often used in tandem setups or multilayer lamination lines.

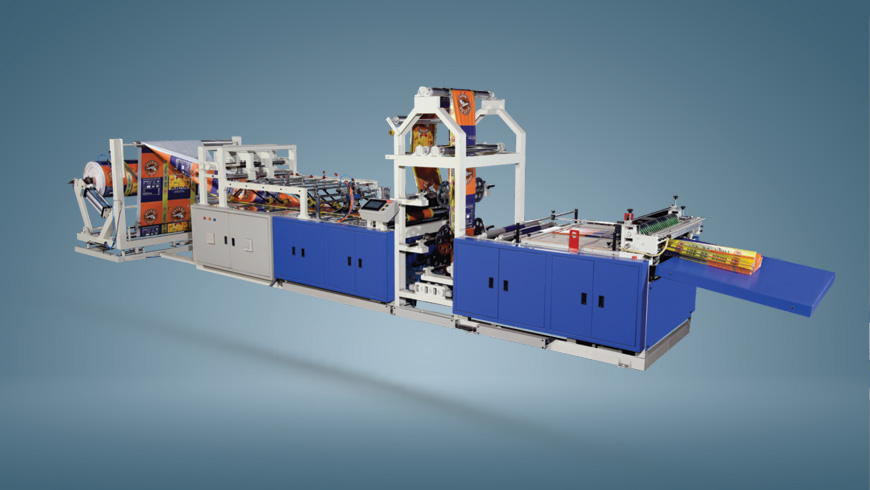

Cutting & Slitting / Woven Sack Finishing Machine

Laser-guided slitting, trimming & sewing automation

Versatile finishing line for woven sacks: precision slitting, trimming, sealing & sewing. Ideal for converting laminated rolls into final bag formats with minimal waste and high speed. Navrang’s portfolio includes automatic woven sack cutting machines, bottom cutters, gusset & twist machines.

Film Laminating Machine

Solvent-based lamination, precision coating

Solvent-based film lamination machine ideal for high-performance packaging applications. Features precision coating technology for improved durability and adhesion. Frequently used for film and foil lamination in flexible packaging. Models are available for a variety of substrates, from films to foils.

Solvent-Based Lamination Machine

High-speed lamination, solvent-based technology

Solvent-based lamination machine for films, papers, and foils. Provides high-speed processing with excellent adhesion properties for diverse packaging materials. Used extensively in flexible packaging, printing, and converting industries.

8-3 Film Laminating Machine

Solventless lamination for flexible substrates

This 8-3 film laminating machine uses solventless technology to laminate films and flexible substrates. Offers enhanced film-to-film bonding and high-quality finish. Ideal for producing packaging materials, labels, and decorative films. Excellent for industries requiring solvent-free solutions.

Production Process

From raw materials to finished products

Material Preparation

Quality raw materials sourced and prepared

Printing

Multi-color printing with precision

Lamination

Layer bonding for strength and durability

Cutting & Slitting

Precision sizing to specifications

Bag Making

Automated production and sealing

Quality Control

Rigorous testing and inspection

Facility Features

World-class infrastructure for premium production

Climate-controlled production environment

ISO 9001:2015 certified facility

24/7 security and monitoring systems

Dedicated R&D and testing laboratory

Energy-efficient production systems

Waste management and recycling units